How to quickly understand the RF RF chip test seat?

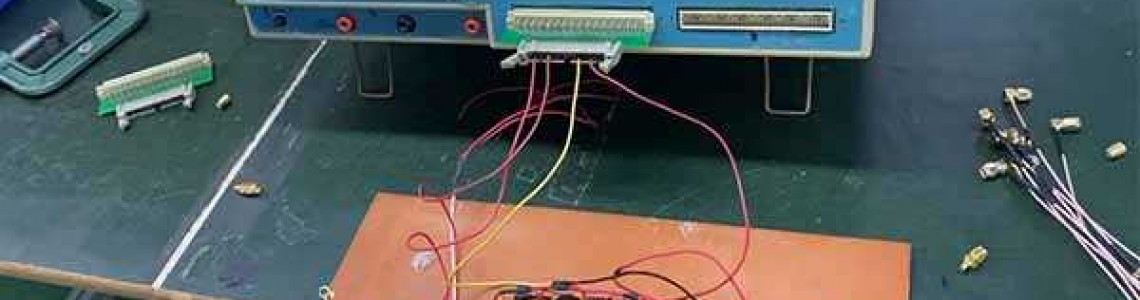

The conventional pin foot of the RF RF test seat still uses the corresponding pogo pin probe, but because the RF transmission signal needs a special medium, the corresponding connector part is also very special. RenhotecIC will explain the knowledge of the RF chip test seat. One of our common RF coaxial connectors is embedded in the test seat for RF conduction.

RF RF test seat defined RF RF test seat is composed of several parts. First, the test seat shell test seat conventional probe RF RF coaxial connector.

RF RF test seat, most of the structure is similar to the normal test seat, except for the coaxial connector part. About the test seat part, also talked about the design idea before. Here's the RF connector.

RF connector, that is, RF coaxial connector, mainly plays the role of communication RF. After the joint efforts of the global communication industry, RF connectors have formed a professional system and international standards, and are also an essential part of connectors.

RF the working principle of RF test seat RF the conventional pin foot of RF test seat still adopts the corresponding pogo pin probe, but because RF transmission signal needs special medium, the corresponding connector part is also very special. One of our more common RF coaxial connectors (RF COAXIAL CONNECTOR) is embedded in the test seat for RF conduction.

The design and selection of RF connectors in the corresponding test seat can be referred to as follows (not limited to the following interfaces), and when customizing the test seat, It is also necessary to propose to the supplier the insertion loss and return loss requirements (i.e. S12/S21 and S11) of its own chip, as well as its own contact impedance requirements:

BNC is a bayonet, For RF connections below 4 GHz, Widely used in instrumentation and computer interconnection. TNC is threaded, A similar BNC, in size 11 GHz, operating frequency Thread type is suitable for vibration environment. SMA is threaded, The most widely used, Impedance is 50 and 75 ohms, Flexible cable with frequency less than 12.4 Ghz,50 ohms Semi-rigid cables up to GHz.26.5 SMB volume less than SMA, To insert a self-locking structure, For quick connections, Often used in digital communication, A L9 replacement, 50 ohms to 4 GHz, 75 ohms to 2 GHz. SMC threaded, Other similar SMB, With a wider frequency range, Often used in military or high vibration environments.

N type connector is threaded, air as insulation material, low cost, frequency up to 11 GHz, often used in testing instruments, there are 50 and 75 ohms. MCX and MMCX connectors are small in size and are used for intensive connections. BMA blind plug connection for low power microwave systems with frequencies up to 18 GHz.

Application of RF RF Test Block

With the upgrading of high-speed communication standards such as 5 G and WIFI6, new RF chips are widely used in mobile devices such as mobile phones, tablets, communication base stations and other communication platforms. The demand for RF RF test seat is more and more high. At present, the main RF chips will use aging test, function test, and special test in extreme environment, so higher test requirements are put forward for RF RF test seat.

RF Method of Making Radio Frequency Test Seat

Product design needs to rely on data, including chip size (length and width), chip spacing, chip shape, chip testing frequency, as well as the corresponding plug loss, back loss and other data. Some RF chips have high power and may need to provide overcurrent requirements. It is well known that the overcurrent capacity pogo pin the test seat is less than 1 A, so the overcurrent capacity of the power pin of the chip also needs to be taken into account. Otherwise, it will affect the chip's full firepower test data.

i.e. Socket RF coaxial connectors (also taking into account isolation)

RF RF test seat maintenance:

If the RF test seat needs regular maintenance, it is best to use a microscope to check the contact probe or RF the RF connector every 5000 times to see if there is dirt on the top of the needle and the wear of the needle. Ensure that the test seat remains in good condition. If there is dirt, it is recommended to use ultrasonic cleaning equipment, put high purity alcohol for ultrasonic cleaning, and then use air gun for final cleaning, to ensure that the test seat is in a dry state, to ensure the service life of the product and test performance. If there is slight wear and does not affect the test (that is, there is no large error in the test data), it can be continued after cleaning. If very serious damage, you need to replace the probe and RF connector to continue to use.

Get in touch if you would like to make some serious savings on your electrical products and RF connector!All its products are from the OEM Original Factory, same quality with much better price. Any questions please feel free to contact us.Continue following us to see what we have prepared for you.

We have focused on the field of electronic connectors. we have unparalleled experience in production and product technology. we have achieved the combination of product quality and technology.

Leave a Comment