introduction of open source cnc module and more

cnc introduction: cnc is the abbreviation of computer numerical control machine tool (computer numerical control), which is an automatic machine tool controlled by a program. the control system can logically process the program specified by the control code or other symbolic instructions, and decode it through the computer, so that the machine tool can perform the specified action, and the rough material can be processed into semi-finished finished parts by tool cutting.

what is cnc?

a cnc (cnc milling machine) is a computer-operated cutting tool that acts as a combined panel saw, spindle shaper and boring machine to carve materials such as wood, metal, plastic and glass into complex shapes.

image

small cnc milling machines can be purchased on a small budget without taking up too much space, and there are plenty of online resources available for those who want to learn how to use them.

as demand for unique products has grown, cnc businesses have made huge profits in online marketplaces like etsy, amazon and facebook marketplace, where customers value small artisan retailers. and to build your own cnc milling machine business, here's what you need to know.

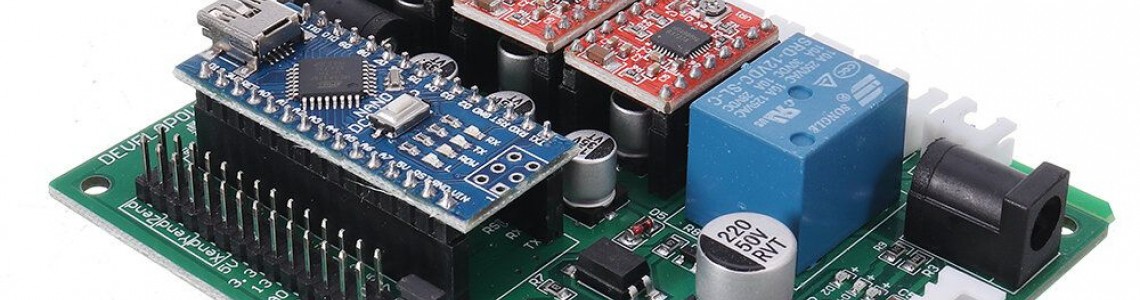

the cnc control features are as follows: integrated motion control system and embedded microcontroller (atmel atxmega192); integrated 4 stepper motor driver (ti drv8818); stepper driver capable of handling 2.5a/winding, this driver motor can be used to handle nema17 engines compatible with most nema23s; allows gcode to communicate via usb; 6-axis control (xyz + abc rotary axis) maps to any 4 of these motors;

find more about cnc module here

Leave a Comment