The working principle and classification of ultrasonic module

What is Ultrasonic Power

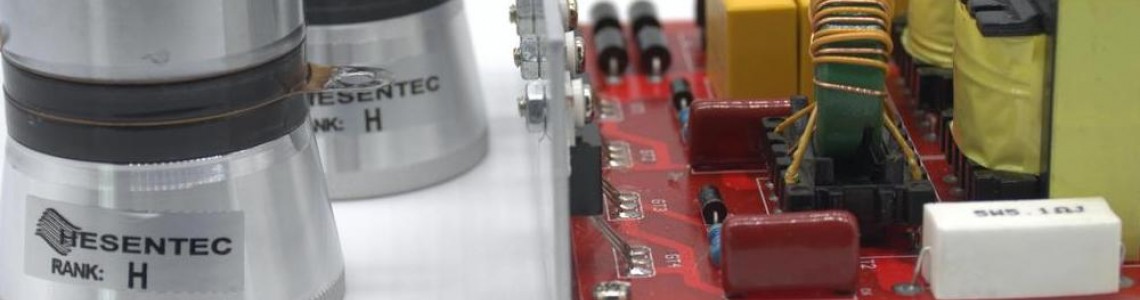

Ultrasonic power sources are often referred to as ultrasonic generating sources, ultrasonic generators. Its function is to convert electrical energy into a high-frequency alternating current signal that matches the ultrasonic transducer. From the form of amplifying circuit, linear amplifier circuit and switching power supply circuit can be used, and high-power ultrasonic power supply generally adopts the circuit form of switching power supply from the perspective of conversion efficiency. The linear power supply also has its unique application range. Its advantage is that the circuit matching is not strictly required, and the operating frequency is allowed to change continuously and rapidly.

The working principle of ultrasonic power supply

An ultrasonic power source, also called an ultrasonic generator, is a device used to generate and provide ultrasonic energy to an ultrasonic transducer. Its purpose is to convert our mains (220V or 380V, 50Hz or 60Hz) into a high-frequency alternating current signal that can match the ultrasonic transducer. This signal can be a sinusoidal signal or a pulse signal.

The ultrasonic screening system is composed of ultrasonic vibrating screen power supply, connecting cable, transducer and resonator. The high-frequency electricity generated by the power supply of the ultrasonic vibrating screen is converted into longitudinal oscillating waves in the form of high-frequency sinusoids through the transducer. These oscillating waves are transmitted to the resonator to make the resonator resonate, and then the resonator transmits the vibration evenly to the screen surface. The materials on the screen are subjected to low-frequency three-dimensional vibration and superimposed with ultrasonic vibration, which can not only prevent the mesh from clogging, but also improve the screening output and accuracy.

Classification of ultrasonic power sources

Ultrasonic power supply can be divided into self-excitation mode power supply and other excitation mode power supply according to the design.

The self-excited circuit has no signal source. It integrates the oscillation, power amplifier, output transformer and transducer into a closed loop. The loop meets the amplitude and phase feedback conditions to form an oscillator with power amplification. and resonates at the mechanical resonance frequency of the transducer. It is generally used in small equipment with a small number of ultrasonic transducers; however, in the case of a large number of ultrasonic transducers, it is impossible to debug to achieve the resonance effect. Therefore, the ultrasonic power supply of industrial ultrasonic cleaning equipment mostly adopts the other excitation method.

The structure of the other-excited power supply mainly includes two parts, the front stage is the oscillator, and the rear stage is the amplifier. Ultrasonic energy is applied to the transducer, typically through output transformer coupling. The circuit of the other excitation mode consists of two parts, namely the signal source part and the signal amplification part.

The signal source part uses the CPU as the core of the signal generation and control part, generally driven by 12-15V voltage, to generate a square wave signal to supply the signal amplification circuit; the timing control, adjustment and other additional functions of the ultrasonic power supply can be controlled by the signal of the signal source. The output mode is completed, using low voltage control, the safety and reliability will definitely be high.

The signal amplification part is to amplify the signal generated by the signal source and output it to the ultrasonic transducer. The difference in output circuit and voltage of ultrasonic power supplies with different circuits is an important reason for the propagation efficiency. When the output voltage is low, the power consumption of the generator is naturally large. At the same time, the vibrator is easy to heat up, and the induced electric field generated is strong. Properly adjusting the circuit and increasing the output voltage to the ultrasonic transducer may achieve good results.

In addition, according to the type of device used in the final power amplifier tube, it can be divided into four types: tube type ultrasonic power supply; thyristor inverter type ultrasonic power supply; transistor type ultrasonic power supply and power module ultrasonic power supply. The electronic tube type and the thyristor inverter type have basically been eliminated, and the transistor type power supply is currently widely used.

Find your RenhotecIC

Leave a Comment